【展会速递】奥普拓涂布智能模头APC智控系统 首登斯图加特电池展

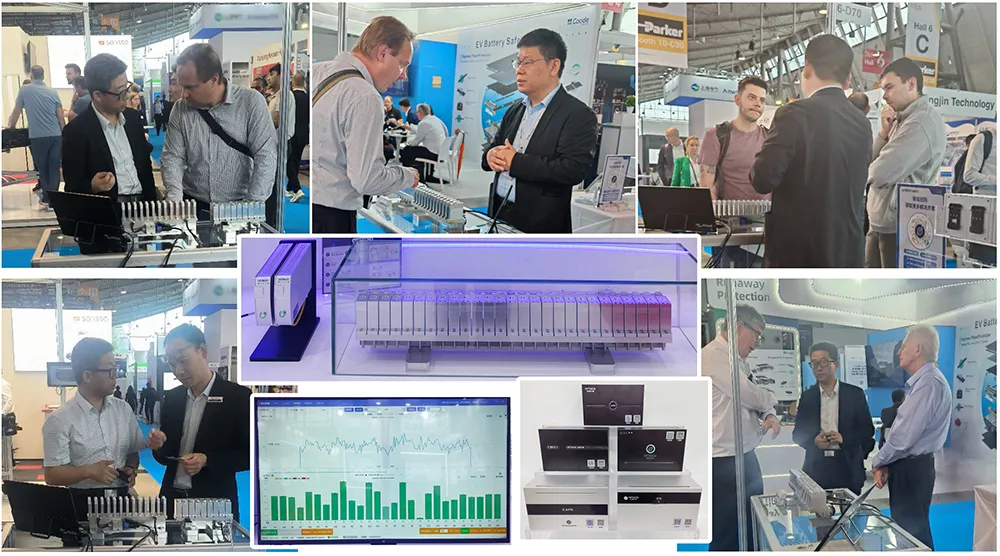

发布时间:2025-06-062025年6月3日—5日,为期三天的欧洲电池与储能电源展览会(The Battery Show Europe 2025)于德国斯图加特展览中心圆满落幕。

这场汇聚全球电池行业精英的盛会,见证了新技术、新材料与智能制造的深度融合。

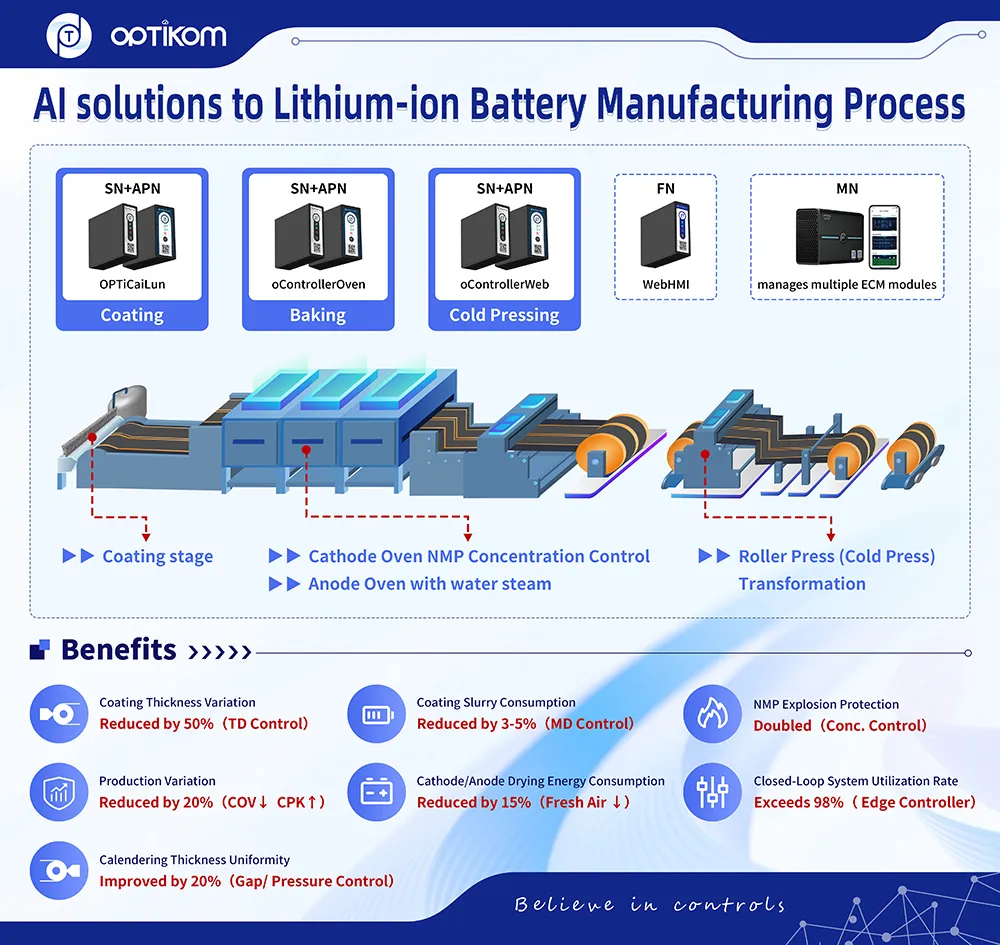

奥普拓携自动涂布闭环控制系统(OPTiCaiLun)和边缘算力模组(OPTiECM)等产品亮相展会。

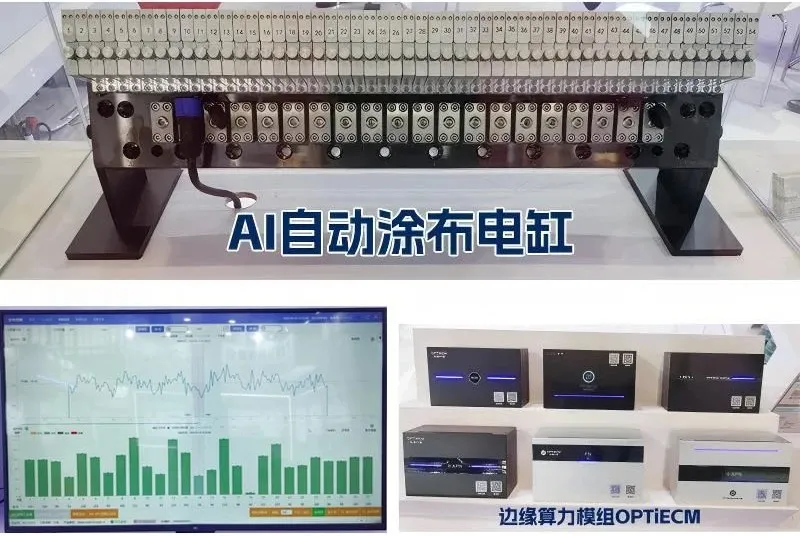

一、高精度微位移电缸+闭环控制系统(软硬件高效协同)

奥普拓自主研发的高精度微位移电缸,依托配套的APC算法(双维平面模型预测控制、系统辨识、仿真算法),不断提升自动调节的智能性和微米级控制精度,已成功助力3C锂电池、动力电池、储能电池等领域客户实现更高效的产线升级。

此涂布闭环智能化控制系统的应用范围,不止于锂电,还可拓展至造纸、薄膜(铜箔铝箔)、印染、烟草、集成电路等多个行业,助力企业提升工艺控制精度,满足质量指标,提高产品性能。

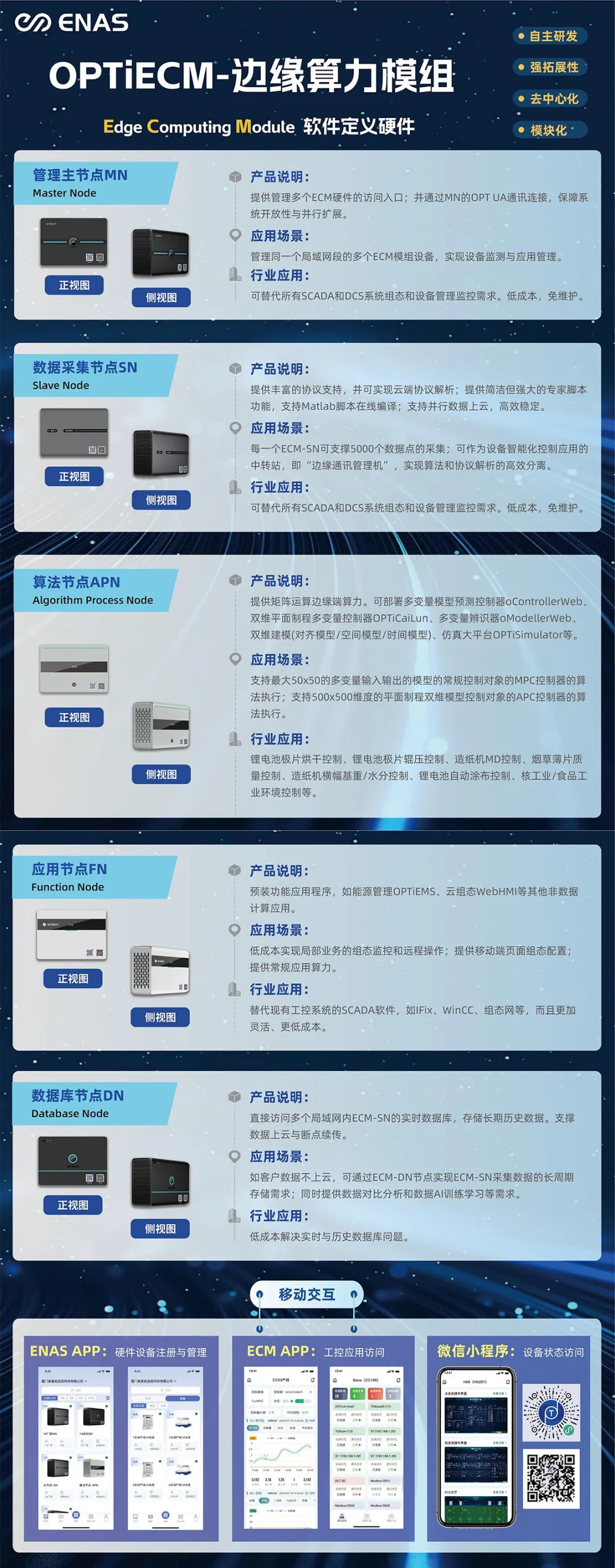

二、云边协同控制系统ENAS

其中,奥普拓还推出了下一代AI驱动的移动工业控制系统ENAS。ENAS具有去中心化、开放性、可扩展、免维护、深解耦等多重优势,可全面替代现有PLC/DCS 层级工控系统,适应未来工厂移动运营新模式。该系统支持接入类DeepSeek大模型,具备模型训练与应用能力。

三、边缘算力模组OPTiECM

作为云边协同架构中的重要一环,OPTiECM能够在靠近数据源的边缘侧提供强大的计算能力。它可以快速处理和分析大量的工业数据,减少数据传输延迟,提高系统响应速度,为工业生产的实时控制和决策提供有力支持,尤其适用于对数据处理时效性要求极高的锂电制造等工业场景。

本次展会,为奥普拓提供了一个与全球客户、合作伙伴以及行业专家深入交流的绝佳平台。通过此次参展,奥普拓不仅展示了其在工业控制领域的先进技术和产品,也进一步开拓了发展视野。奥普拓将继续为工业企业的智能化改造和制造业数字化转型提供更具创新性的产品与服务。

The Battery Show Europe 2025, a three-day event held from June 3 to 5, successfully concluded at Stuttgart Exhibition Centre in Germany.

This global gathering of battery industry elites has witnessed the deep integration of new technologies, advanced materials, and intelligent manufacturing.

OPTiKOM CONTROL showcased its latest products at the exhibition, including the automatic coating closed-loop control system(OPTiCaiLun) and the Edge Computing Module(OPTiECM).

High Res. Actuators + closed-loop control system (high-efficiency collaboration between software and hardware)

Relying on the supporting APC algorithm (2D plane model predictive control, system identification, simulation algorithm), the High Res. Actuators independently developed by OPTiKOM CONTROL continuously improves the quality of automatic adjustment and control accuracy(micron-level). It has successfully helped customers in fields such as 3C lithium-ion batteries, EV and energy storage batteries achieve more efficient production line upgrades.

The application scope of this coating closed-loop intelligent control system is not limited to lithium-ion battery but can also be extended to multiple industries such as papermaking, films (copper foil and aluminum foil), printing and dyeing, tobacco, and integrated circuits, helping enterprises improve process control accuracy, meet quality indicators, and enhance product performance.

ENAS:Edge Networking Automation System

Among them, OPTiKOM CONTROL also launched the next-generation AI-driven mobile industrial control system ENAS. ENAS has multiple advantages such as decentralization, openness, scalability, maintenance-free, and deep decoupling. It can fully replace the existing PLC/DCS hierarchical industrial control system and adapt to the new mobile operation model of future factories. The system supports access to large models like DeepSeek and has model training and application capabilities.

OPTiECM:Edge computing module

As an important part of the cloud-edge collaborative architecture, OPTiECM can provide powerful computing capabilities at the edge close to the data source. It can quickly process and analyze large amounts of industrial data, reduce data transmission delays, and improve system response speed, providing strong support for real-time control and decision-making in industrial production, especially suitable for industrial scenarios with extremely high requirements for data processing timeliness, such as lithium battery manufacturing.

This exhibition provided OPTiKOM CONTROL with an excellent platform for in-depth communication with global customers, partners, and industry experts. Through participating in the exhibition, we not only showed the world its advanced technologies and products in the industrial control field but also further broadened its development vision. We will continue to uphold the spirit of innovation, deeply cultivate the industrial control field, and provide higher-quality products and services for the intelligent transformation of industrial enterprises and the digital transformation of manufacturing.